Texas A&M Senior Capstone Project: Passive Upperbody Exoskeleton

As the culminating design experience for my bachelor’s degree, I worked with a team of five other mechanical engineering students to design and prototype a passive, upper body exoskeleton. Unlike most capstones, my group’s project was funded by an entrepreneurship fund, resulting in us having to develop our own project goals, restrictions, and success metrics prior to designing our exoskeleton. Our research showed that the most frequent injuries in the workplace were the result of repetitive strain rather than any single event injury, which makes sense given the huge push towards safer work environments and the rise of assembly-line-like work.

We began our design phase by researching how other exoskeletons have worked to solve Repetitive Strain Injuries (RSI) in the workplace and where their designs fell short. We found other exoskeletons were bulky, heavy, and very expensive.

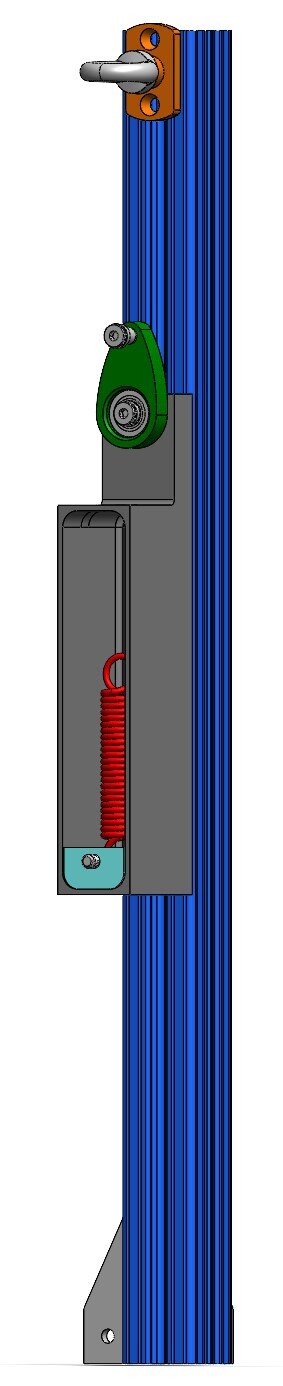

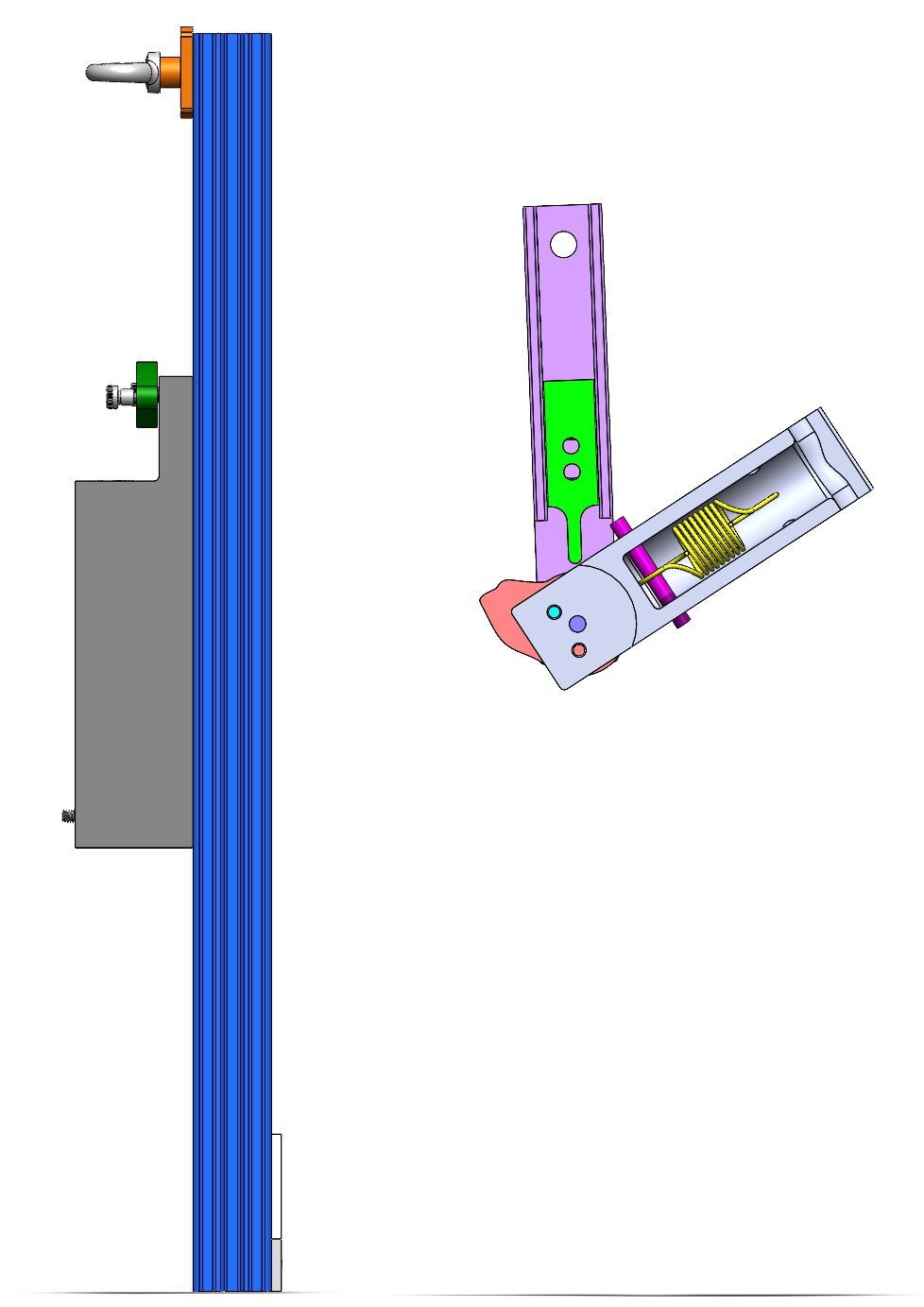

We then began to break down the functions of an exoskeleton into solvable pieces and brainstorming concepts. After deciding on an upper-body assistance exoskeleton, the team broke into two sub-teams, an arm team and a back team, to better work through turning the concept into a prototype.

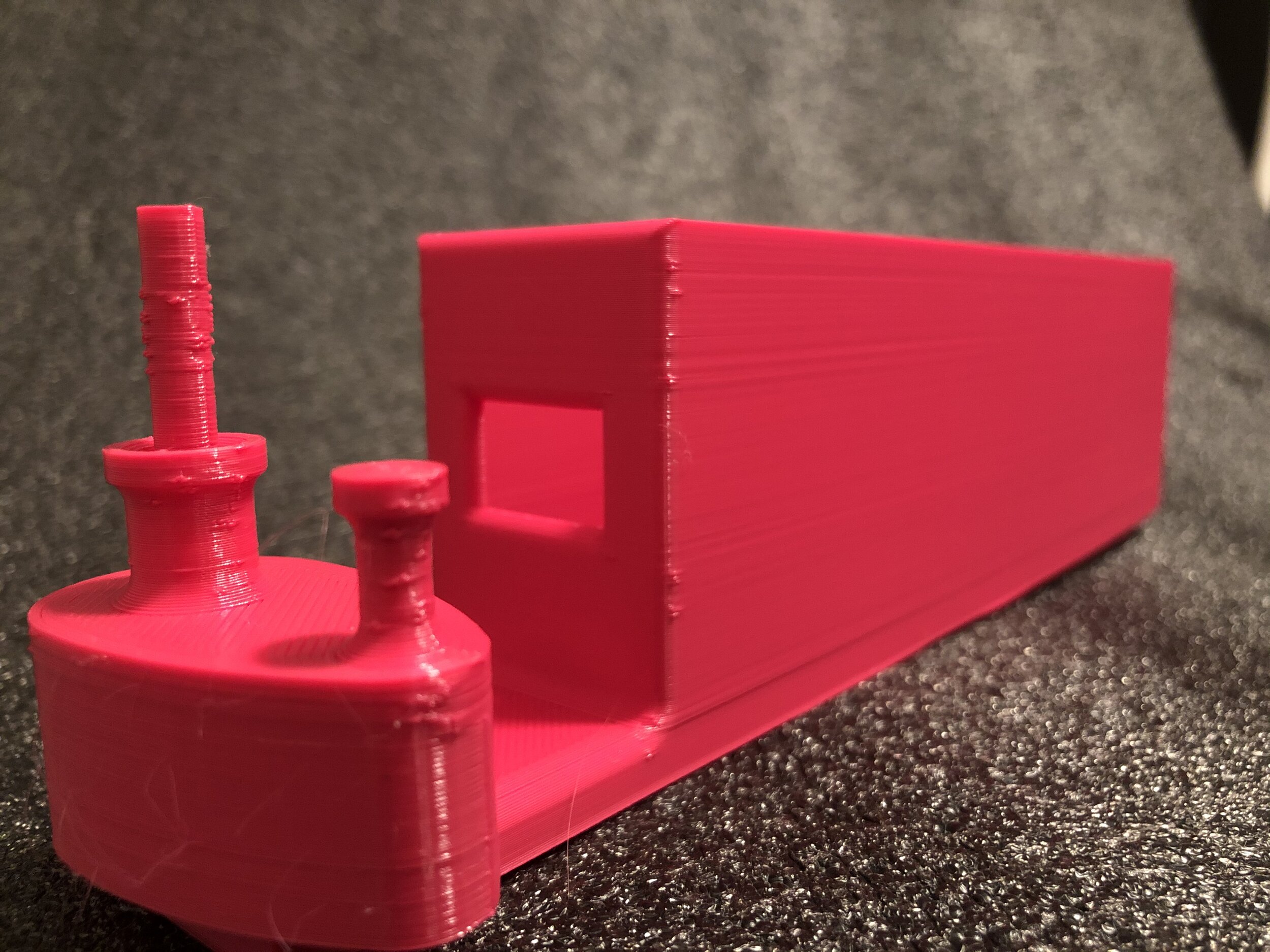

After several iterations, including a scaled-down 3d printed version, a fully fabricated prototype was constructed. Assembly of the final prototype was the first time the team met up in person due to the pandemic, despite this the exoskeleton was able to be completed ahead of schedule.

My main contributions to the project were in project management and the complete development of the shoulder subsystem. Below are some pictures from the development process and final prototype.

Additionally, a 3d model of the arm subsystem can be interacted with at Spline Exoskeleton Viewer