MEEN ‘21 Scissor Lift Competition

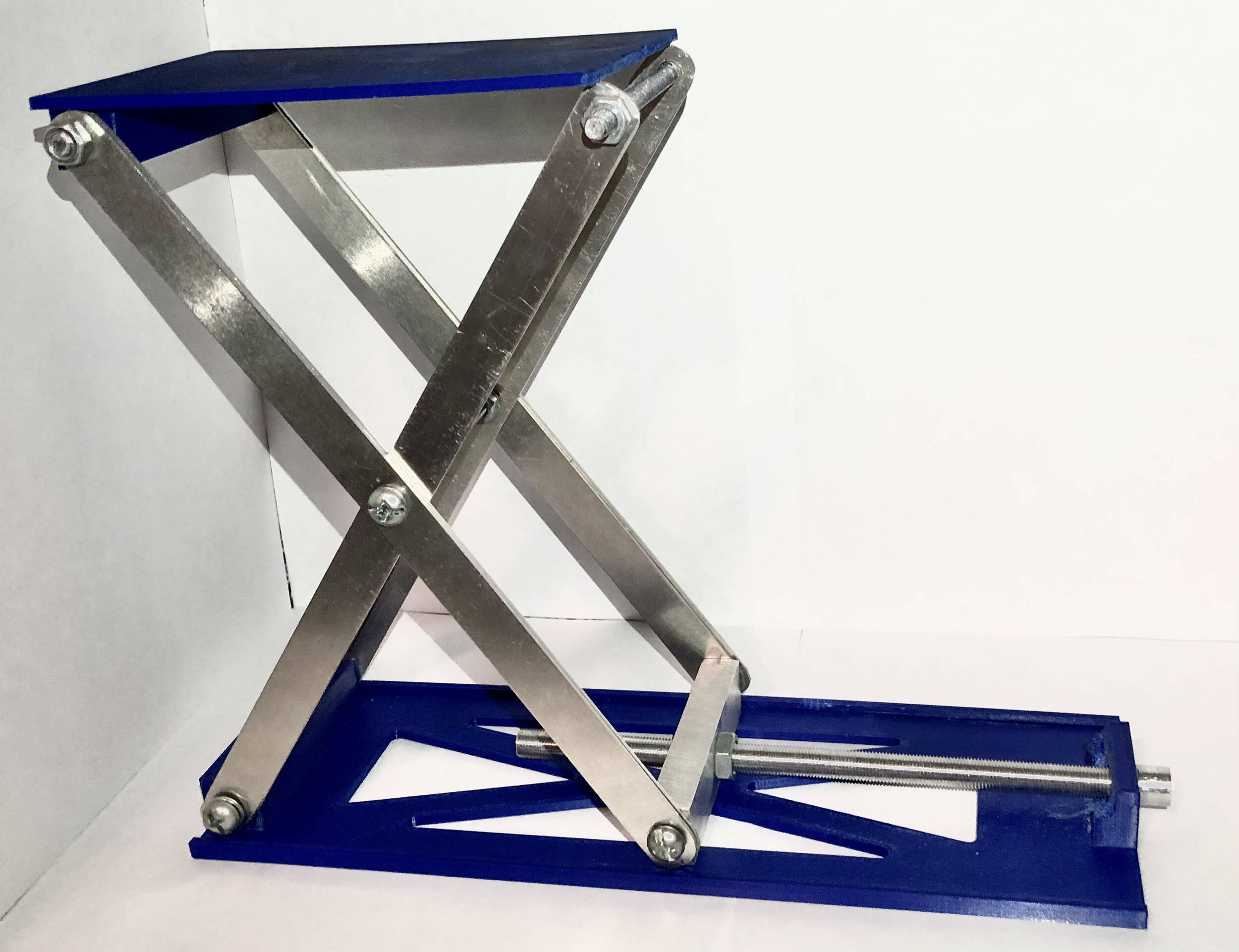

In the class “Materials and Manufacturing Selection in Design,” the term project was to manufacture a small scissor lift using the machine shop and 3d printing. A basic design was given, with modification highly encouraged. At the end of the semester all of the group’s scissor lifts were tested on the following criteria:

Ability to hold 2 Kgs

Height during “closed” configuration

Height during “elevated” configuration

Total deflection

The Competition Results

My group was able to make a scissor lift that exceeded the competition's goals. A last-minute change to our design was to cut the top of the scissor lift in half to eliminate the heat deformation from the 3D printed part. My group’s scissor lift was the lightest of all the designs and had a deflection of only 3 mm when under load. Unfortunately, 3 mm was too much to earn first place.

———————————

Working with my group to make a physical project was very different than simply making a presentation or report like most previous class projects. This project helped me to improve my time management skills, especially when respecting other people’s time. I also learned, threading a 9” lead screw by hand is both time-consuming and very likely to fail.